Why U.S. Fashion Brands Are Shifting Production to Turkey

In today’s global fashion industry, brands are facing increasing pressure to optimize their supply chains. From skyrocketing import duties to long transit times and compliance concerns, sourcing apparel from traditional markets like China and Southeast Asia has become more challenging than ever. As a result, many American fashion brands are now turning to Turkey — and for good reason.

At Clothing Supplier, we specialize in helping brands make a seamless transition to Turkish manufacturing through our strategic sourcing engine, CLOS. Here's why producing in Turkey is not just a trend, but a long-term strategic advantage.

Lower Import Duties, Higher Margins One of the most compelling reasons for U.S. brands to consider Turkey is the significantly lower import duties. Compared to sourcing from China or Southeast Asia, importing goods from Turkey can result in substantial savings. These reduced tariffs directly translate to improved profit margins, especially when ordering bulk quantities of men's, women's, or children's apparel.

Speed and Efficiency in Logistics While ocean freight from Asia can take up to 40 days, Turkey offers a faster alternative. With express services like DHL and FedEx, shipments can reach the U.S. in just 3 to 5 days. This speed allows brands to reduce lead times, restock quickly, and respond to market demands without the delays associated with long-distance sourcing.

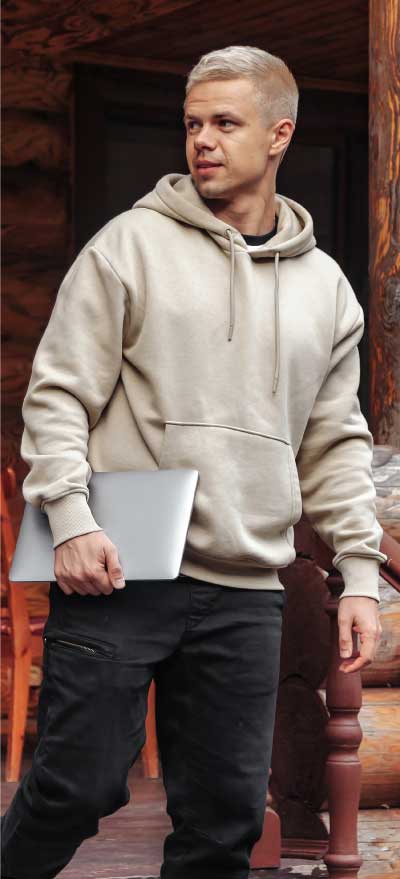

Flexible Production Options With Clothing Supplier and CLOS, brands enjoy flexible minimum order quantities starting as low as 100 units. This enables small and mid-size brands to test the market without large upfront investments. Whether you're launching a new collection or need a quick restock of bestsellers, Turkish manufacturers can scale production to match your needs.

Transparent, Ethical Manufacturing Turkey’s garment industry is known for its strong commitment to ethical and sustainable practices. At Clothing Supplier, we work exclusively with factories that are ISO, BSCI, SEDEX, GOTS, and GRS compliant. From audit-ready documentation to environmentally responsible processes, we ensure every step of production meets global standards.

End-to-End Sourcing with CLOS Our production model goes far beyond simple manufacturing. Through our local team at CLOS, we manage the entire process: fabric sourcing, factory selection, price negotiation, quality control, logistics, and documentation. With over 15 years of experience and 100+ active international clients, CLOS becomes your eyes and ears on the ground in Turkey.

A Smarter Way to Manufacture The global supply chain is shifting. Brands that adapt quickly will gain a significant advantage. With Clothing Supplier and CLOS, you get a sourcing partner who understands both the Western market demands and the local manufacturing landscape.

So, if you’re tired of rising costs, long delays, and uncertain compliance, it’s time to consider Turkey as your next production hub. Reach out to Clothing Supplier and discover a smarter, faster, and more profitable way to build your brand.